Professional Team

5 designers with the title of engineer or above, 2 full-time material engineers, 6 technicians, all of whom have worked in well-known domestic and foreign companies;

Strong strength

Yancheng has a production base with a total investment of 120 million yuan. The plant covers an area of 6,000 square meters, of which the total investment in equipment is about 35 million yuan.

Quality Assurance

Choose aerospace materials, low wear; excellent and reasonable design of internal structure and overall machine; precise processing equipment, standardized production process workshop, quality assurance.

After-sales guarantee

Rucca promises to respond within 2 hours when receiving the buyer's report for repairs, provide a solution within 24 hours, and offer free damaged parts in warranty period.

Related Products

More items about pin bead mill

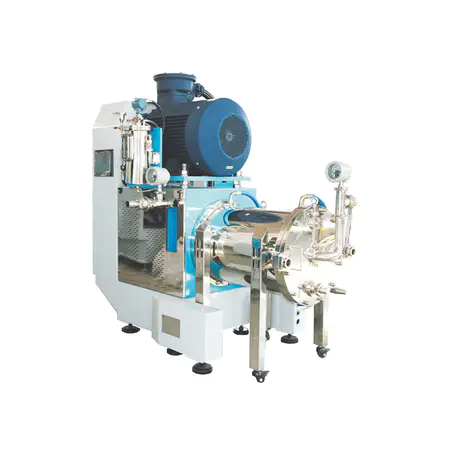

RUCCA pin bead mill

Rucca is a famous producer and designer of wet grinding and dispersing equipment in China,product list:Inline Dispersing System,Full Series of Bead Mills,Basket Mill,Mixing machine such as High Speed Disperser,Dual Shafts Mixers,Triple Shafts Dissolver,High Shearing Homogenizer,Grinding Beads,and Whole Production Line.

Nano Pin Bead Mill

Nano Bead mill grinding structure (system): pin (pin)/disc/turbocharger/basket with separate drive for stand-alone centrifugal separation system. This vertical structure enables a thorough grinding process, enabling the finest and narrowest particle distribution down to the nanometer scale. They are ideal for colorants, pigments, dyes, furniture paints, automotive paints and more, especially UV inks and offset printing inks.

Nano Pigment Pin Bead Mill

Nano Pigment Pin Bead Mill, high efficiency and energy saving, suitable for high flow and ultra-fine grinding, saving 30% energy. Grinding fineness: ultra-fine nanometer. Suitable for battery anode materials, MLCC, ceramic inks, food additives, cosmetics, coatings, inks, pigments, etc.

Ceramic Ink Pin Bead Mill

The ceramic ink bead mill adopts a unique large-area tubular separator, which can separate accurately and smoothly, and solve the problems of slow discharge speed and clogging of grinding media. It can use ultra-fine grinding media and the smallest discharge screen can be 0.05.

Ceramic ink bead mill is suitable for low temperature requirements and fine particle size requirements. Suitable for high-efficiency ultra-fine industrial continuous production. It is suitable for materials with high solid powder and liquid content and high refining requirements.

Battery Pin Bead Mill

Anode materials mainly include carbon anode materials, alloy anode materials, carbon nanotubes, nano-alloy materials and nano-oxide materials. The battery pin bead mill is mainly used to grind nanometer fineness materials.

Frequently Asked Question

Do you have any question?

In terms of rotor structure, there are disc sand mills, pin-pin sand mills, and turbine sand mills. From the material of rotor and grinding cylinder, there are rubber (rubber-coated iron), metal, ceramic, silicon carbide

Applicable viscosity of rod pin bead mill: below 20000cps